“We’re making it easier than ever to address this through automatic sensing, as a critical and efficient part of flight line testing. “Contamination in the fuel tank can cause an incorrect fuel level indication,” said Guy Hill, Director of Avionics Test Products, VIAVI. During this time, VIAVI has supported system testing of over 200 aircraft platforms, from the Airbus A300 to the V-22 Osprey. This portfolio has supported fuel quantity system testing of rotary and fixed-wing aircraft for over 30 years as part of Goodrich Aerospace, then Aeroflex, and now VIAVI. The PSD90-3 replaces previous test sets including the PSD30-2AF, the PSD60-2R, the PSD60-1AF and the PSD90-1C. PSD90-3 is suitable for flight line testing on battery power or bench testing on external power. The PSD90-3 Fuel Quantity Test Set accesses the Fuel Quantity Indicating System (FQIS) through an interface which is unique to each aircraft.

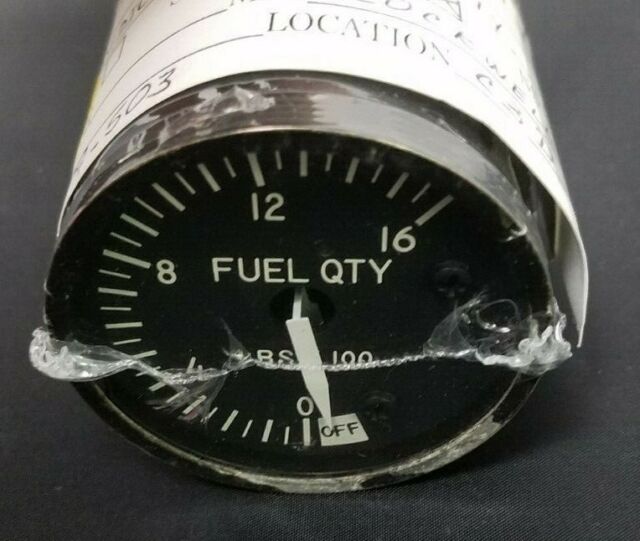

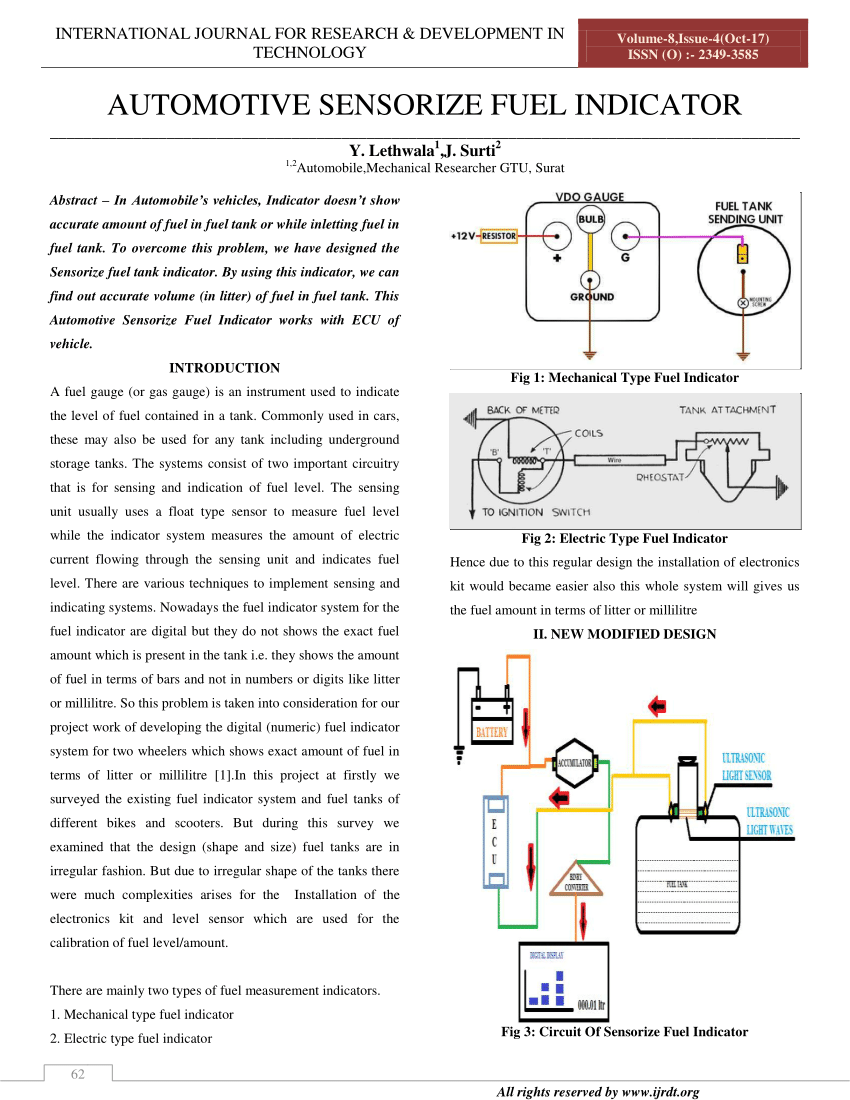

During normal capacitance measurements, the contaminated fuel probe detection function will automatically alert the user via a Percent of Error indication on the display and with a Contaminated Fuel Probe Detected LED on the front panel. The PSD90-3 Fuel Quantity Test Set provides users with two methods, Auto and Manual, for detecting and isolating contaminated fuel probes caused by particulates, water, microbial growth, or other sources of contamination. These microorganisms feed on the hydrocarbons in the fuel to produce a substance that can reside on fuel probes, causing a fouled probe which can lead to incorrect fuel level indication, a problem that can go undetected for some time. Particulates and moisture present in fuel significantly promote bacteria and fungi growth. FQIS or other wires entering the fuel tank (such as fuel level sensor systems (FLSS), float switch, etc. Uniquely, the test set includes automatic detection of probe contamination, an issue for commercial and military aircraft worldwide. The PSD90-3 will test any AC or DC capacitive fuel, water, liquid oxygen (LOX), or engine oil system. The test set allows the user to test, troubleshoot and isolate fuel system issues, calibrate fuel quantity indicators and detect contaminated fuel probes. The low level sensing system is powered by 28 vdc.Viavi Solutions has unveiled its new PSD90-3 Fuel Quantity Test Set for Commercial & Military Aircraft at AEA 2023. The L or R FUEL LOW light capsule is lighted when the relay releases. When the resistance of the thermistor decreases, the relay releases as the bridge approaches a null condition. The output signal which results from the imbalance is amplified to operate a relay. The thermistor is part of a normally unbalanced bridge circuit in the thermistor control unit. Its temperature then rises and its resistance decreases. NO BREAK - WORK HARDER When the fuel quantity falls below the 20 percent level, the thermistor in the low fuel sensor is no longer cooled by fuel. NO BREAK - WORK HARDER The low level sensing system includes a dual thermistor control unit in the console, a low level sensor in each center tank unit at the 20 percent level, and two capsules, L or R FUEL LOW in the master caution panel. The indicator is powered by 115 vac and electrical connection is through a connector at the rear of the indicator. NO BREAK - WORK HARDER The rear of the indicator contains four adjustments for full and empty calibration, two for the dial and two for the digital readout. The variable resistor wiper arm is mechanically linked to a counter mechanism which displays the total fuel quantity in pounds. A printer on the wiper shaft moves across the calibrated scale and indicates the quantity in single-tank quantity indication. The servo motor moves a variable resistor wiper arm thru reduction gears to reestablish the bridge balance. This signal is amplified to drive a servo motor. The unbalance results in a gage correction signal at the bridge output. This causes an unbalance in the fuel quantity indicator bridge circuit. A change in fuel level causes a change in the capacitance of the tank units. NO BREAK - WORK HARDER The indicating system includes the fuel quantity selector switch and indicator clamp mounted on center instrument panel, and ten tank units, one in each forward or aft aux tank and three in each main tank. TM 55-1520-240-23-7 8-57 MISCELLANEOUS INSTRUMENTS (Continued) 8-57 FUEL QUANTITY INDICATING SYSTEM Description This system includes the fuel quantity indicating system and a low level sensing system.

0 kommentar(er)

0 kommentar(er)